Hardware Deployment¶

Controller development can be a messy process involving a patchwork of software tools, hardware configurations, and algorithm parameters - but it doesn’t need to be. Pure software development often follows a highly structured process designed to ensure both reliability of the output and engineering efficiency. While hardware development by its nature will always be a different beast than pure software, we can take inspiration from workflows incorporating continuous integration, automated testing, and version control to imagine a process with much less friction.

In this tutorial we will go through one such workflow to see how Python and Archimedes can act as a unifying high-level layer enabling a logical development progression. The result is a straightforward development cycle with the potential for faster iteration, improved validation, and reduced hardware risks.

This workflow assumes that the hardware itself is fixed, though of course the controls development could be embedded in a broader design loop for hardware iteration.

Tutorial overview¶

Our example application and control algorithm will be as simple as possible: a brushed DC motor controlled by PI feedback. This will let us focus on the development process, which can scale to more complex systems, without getting bogged down in the application-specific physics and algorithm details.

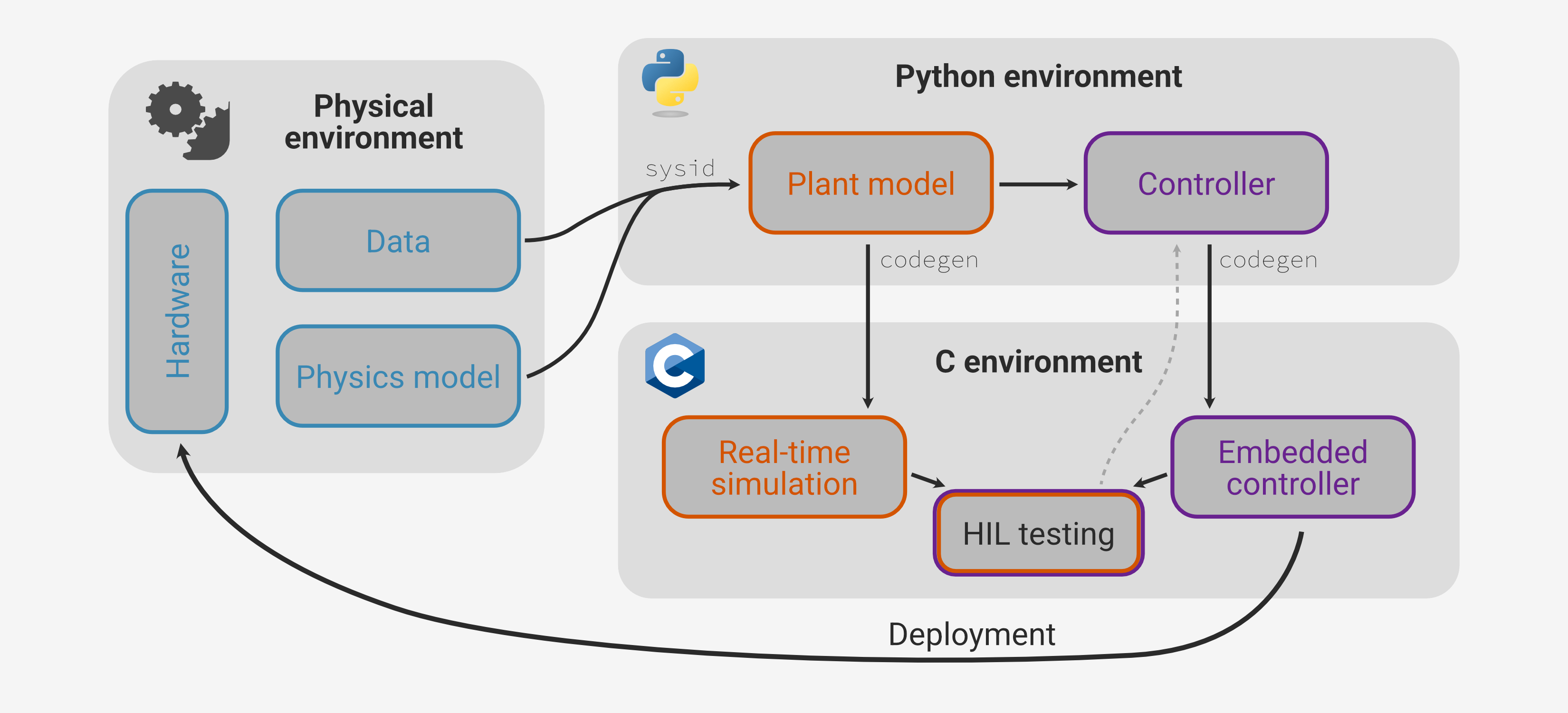

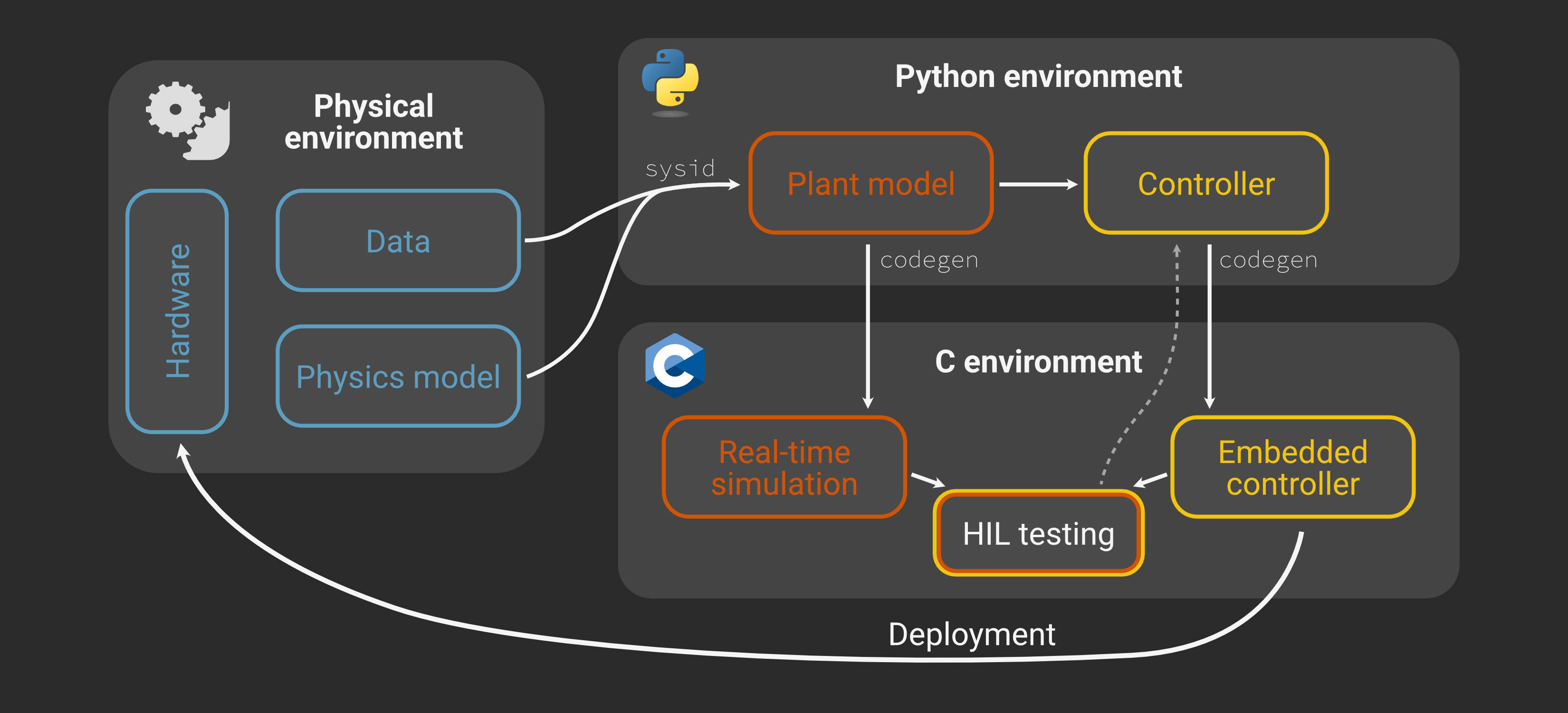

As mapped out in the figure above, we will start by constructing a first-principles model of the system and collecting some characterization data. We can then apply parameter estimation to calibrate the physics model using the test data, resulting in a “plant” model. We will design a controller based on the plant model and simulate its performance - all in Python.

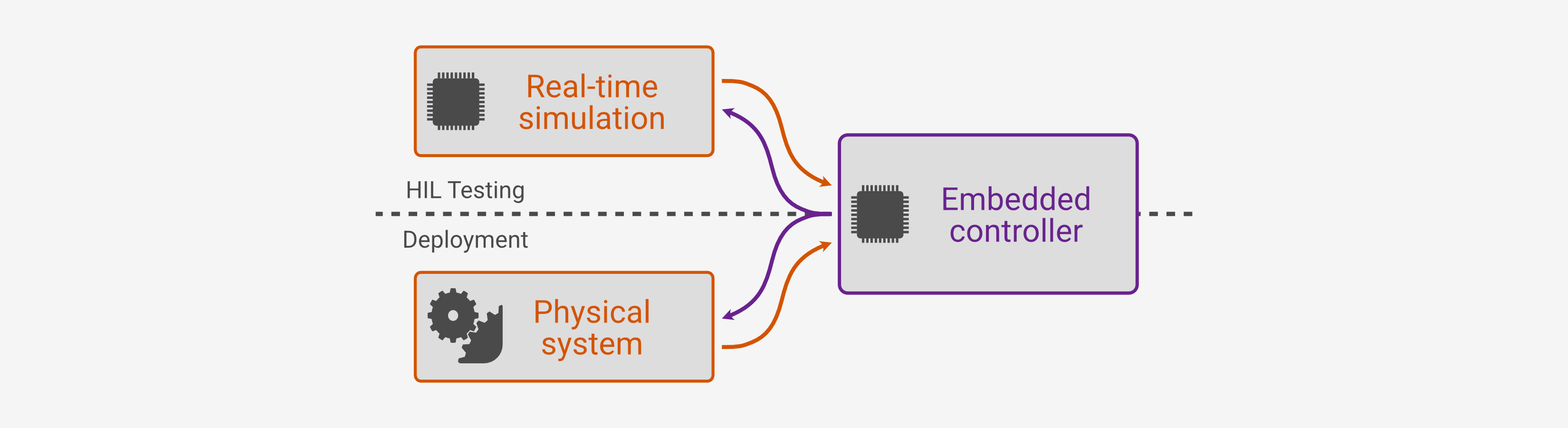

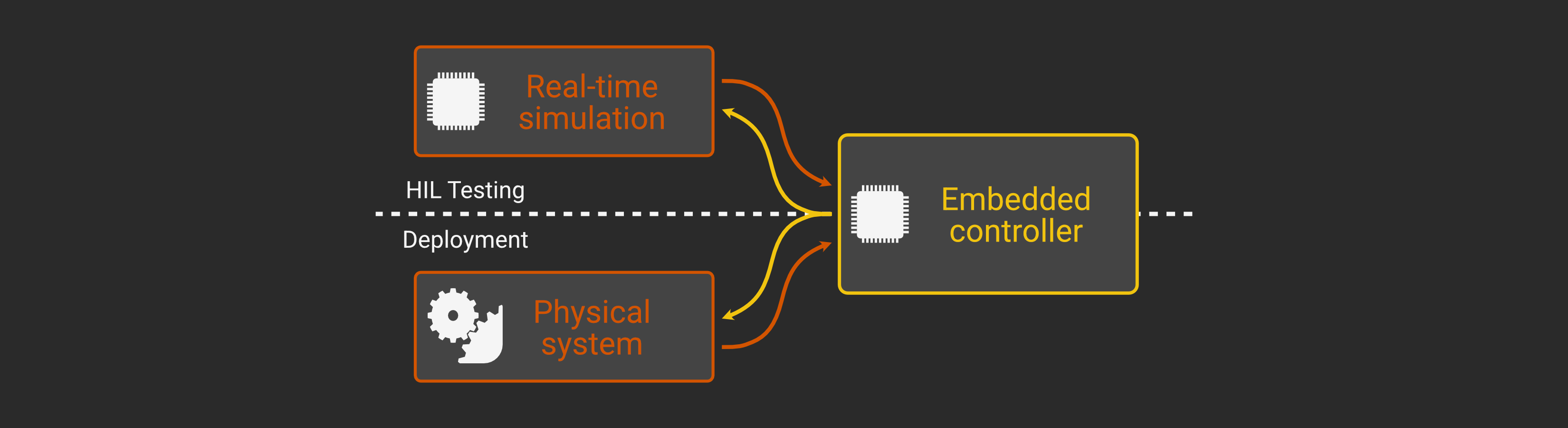

In principle, we could then simply generate C code corresponding to the Python control algorithm, deploy to hardware, and evaluate performance on a test system. However, here we will explore incorporating an additional stage of the controller development: hardware-in-the-loop (HIL) testing. Using the same code generation mechanisms, we can construct a real-time simulation of the plant model and connect this to the controller board - as far as the controller knows, it is sensing and actuating the real system.

While HIL testing is often relegated to late-stage validation for compliance requirements, it can also be a valuable testing stage to catch costly or difficult-to-debug errors before deploying to the real hardware.

This end-to-end workflow tutorial provides an example of how Archimedes can be used as the backbone of a modern, structured approach to rapid development iteration. While simplified (and applied to a simple physical system), every aspect of the process can scale naturally to more complex workflows and systems.

Outline¶

-

Brushed DC motor and physics model

Motor driver circuit

The STM32 controller board

Bill of materials (if you want to build it yourself)

-

Configuring the STM32

Collecting step response data

Implementing the physics model

Calibration via parameter estimation

-

Implementing a simple PI controller

Classical control systems analysis

C code generation

-

Setting up a real-time simulator

The analog communication circuit

Generating code for the real-time model

Evaluating the controller

-

Running the same controller on the physical system

Comparing to HIL testing results

Key takeaways

Prerequisites¶

This tutorial integrates several Archimedes concepts, including structured data types, C code generation, and system identification. We’ll introduce them as needed, but it will be easier to follow if you are already comfortable with these concepts - the following documentation pages are a good place to start:

Beyond Archimedes specifics, the tutorial only assumes basic physics and control systems knowledge (an RL circuit and proportional-integral control), though familiarity with the Python Control System Library may be helpful in the controller design section.